Equipment and Technology

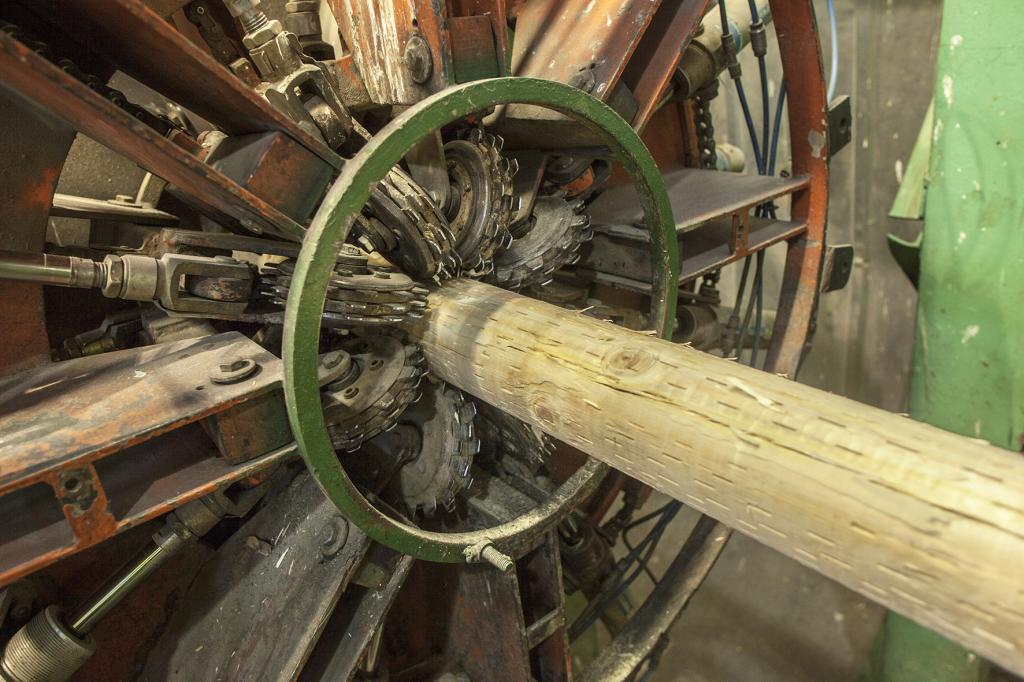

The facilities of Palmako AS are equipped with machinery by well-known and acknowledged manufacturers such as Weinig, AMD, Grecon, Rex, Minda, Harko. The technology has been manufactured considering the character of Palmako’s production, providing high efficiency and quality. Over the years, around €45 million has been invested in top technology.

The company-wide quality management system of Palmako AS covers the entire production process and ensures the conformity of the final product with the established quality requirements. All the processes in the company are supported by business software, which enables data observation, starting from sales and production planning to stock levels and deliveries.

In production units, workplace organisation method 5S is used – Sort, Set in order, Shine, Standardise and Sustain.

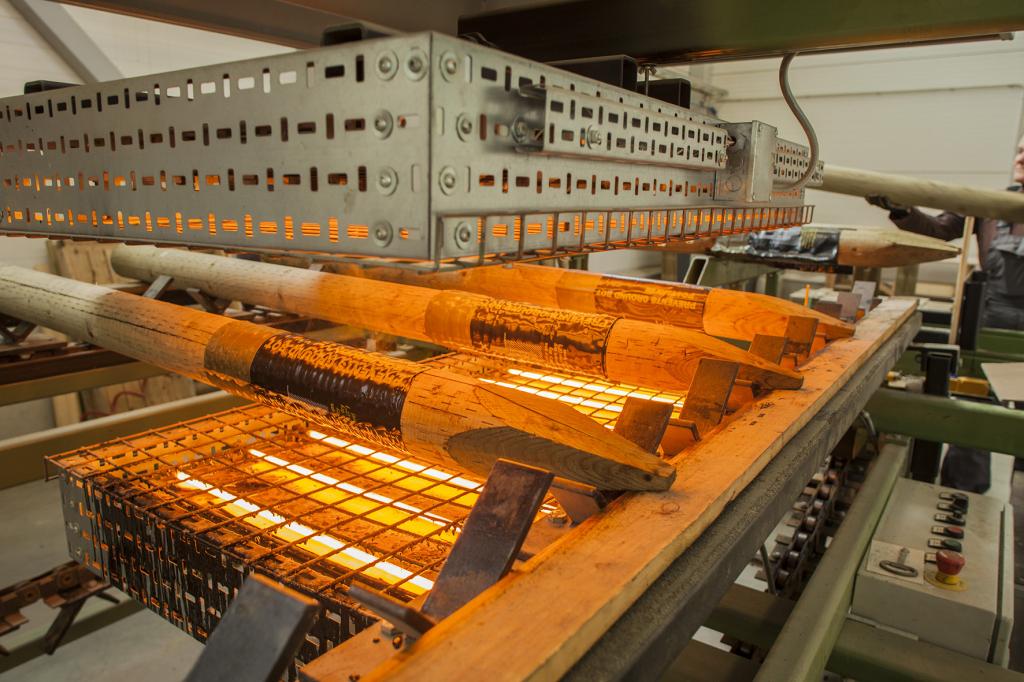

Treatment as Additional Protection for Wooden Products

To prolong the lifetime of the product and preserve its appealing appearance, it is recommended to treat natural timber with a wood preservative agent as soon as possible. Unprocessed wood becomes greyish after having been left untouched for a while and can turn blue and become mouldy. Treating wood with a preservative effectively protects against wood-destroying fungi, insects and wood rot. Therefore, it is recommended to use the Palmako AS product treatment service. Treating means that you do not have to treat surfaces with an oil primer and undercoat. Depending on the product type Palmako is able to treat the products in a variety of ways.

Dipping

Palmako has treatment baths for brown, grey and clear white dip treatment. Cabins and other larger sized items can be ordered treated with Axil 3000 P by the Sarpap & Cecil Industries water-soluble treatment liquid, guaranteeing treatment within classes 1-3. In addition to wood-protecting components, which provide resistance against biological damage and UV radiation, this primer can contain up to three pigments. The brown and grey dipping treatment can enhance the colour of your product, but the clear white dipping works best for the pre-paint preparation stage. The pigment fades gradually over time but this does not have a negative effect on the performance of the treatment.

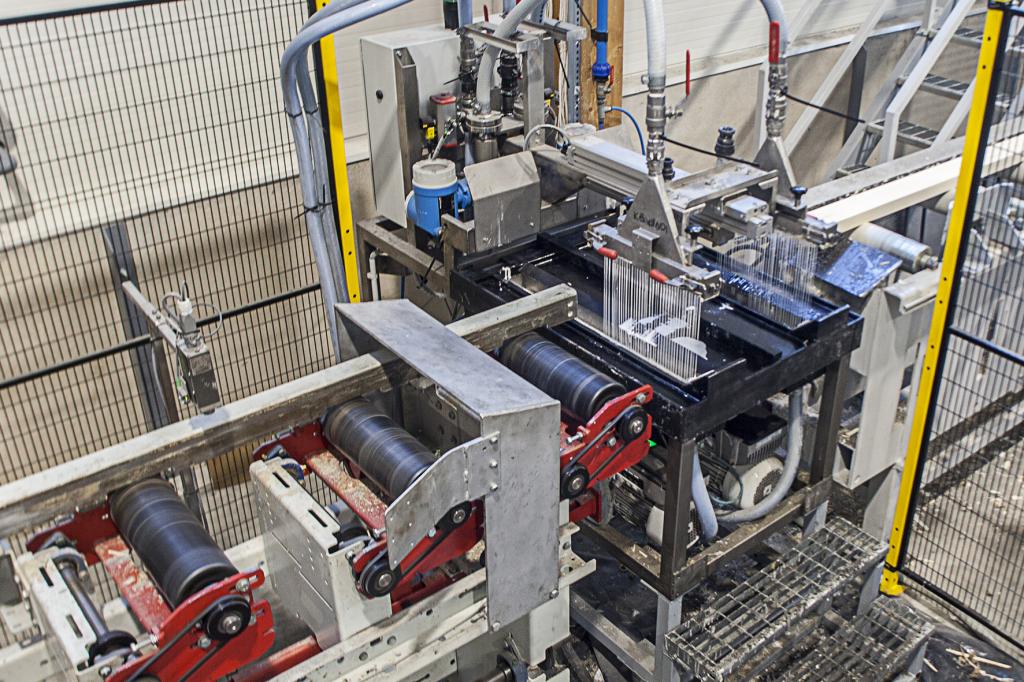

The treating process involves immersing the entire product in a bath of treatment liquid for approximately 30 minutes, enabling the treatment to penetrate every element. The product is then allowed to air dry before it is packaged.

Dip treatment enables treatment to penetrate areas of the product that cannot be reached when stains are applied by brush. To ensure the best protection against UV radiation, dirt and mechanical damage, topcoat should be applied as soon as possible. It is important to follow the paint manufacturer's instructions. Treated wood must be finished with at least two coats of topcoat. It is important to remember that all wood must be dry when it is painted.

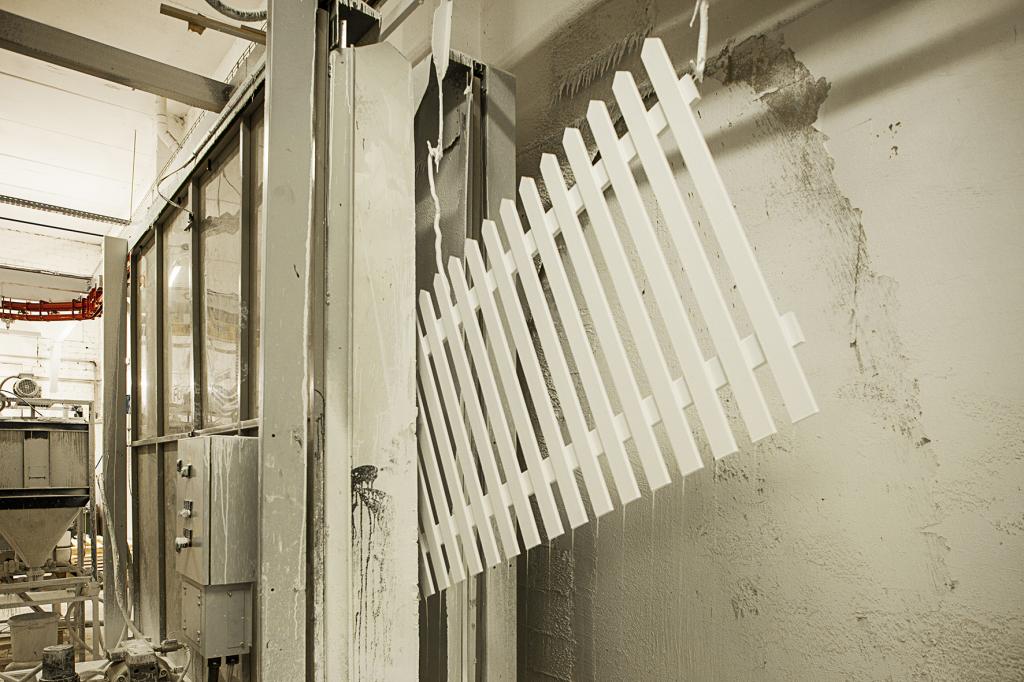

Painting

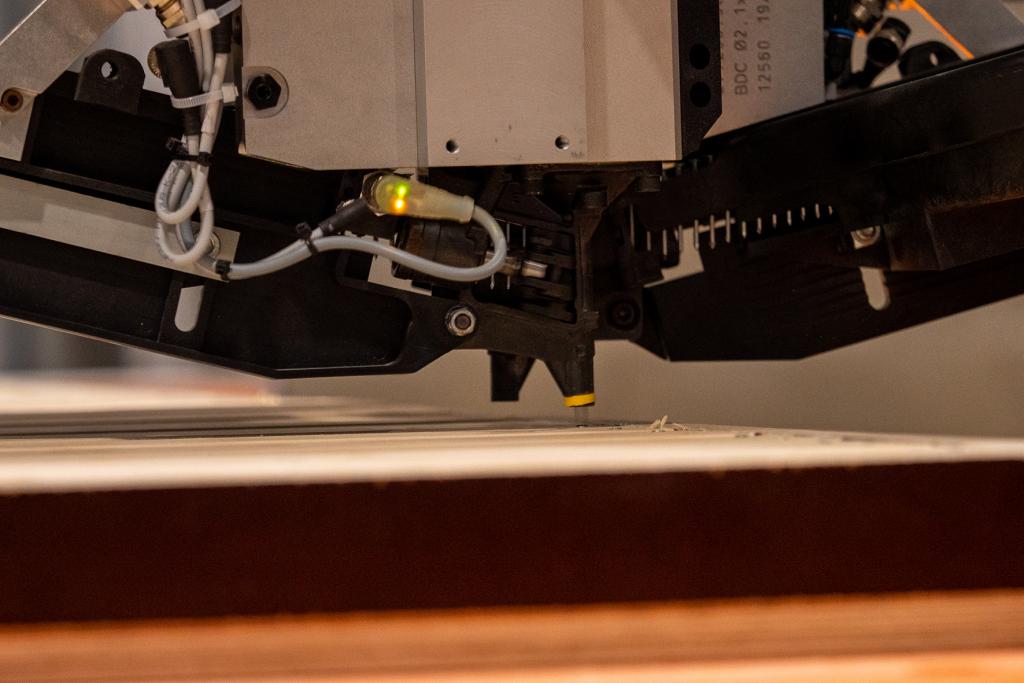

Palmako AS has invested in modern painting technology that enables smaller sized garden products like fence panels and posts to be painted. Today, it is possible to paint the products white and grey, using the advanced flowcoating method and spray chamber method. The humidity of the painting room is controlled by a moistening system, which aims to achieve the necessary environment for painting. After painting, the products will dry in a 30-metre-long drying chamber, where the whole drying process can be adjusted and observed.

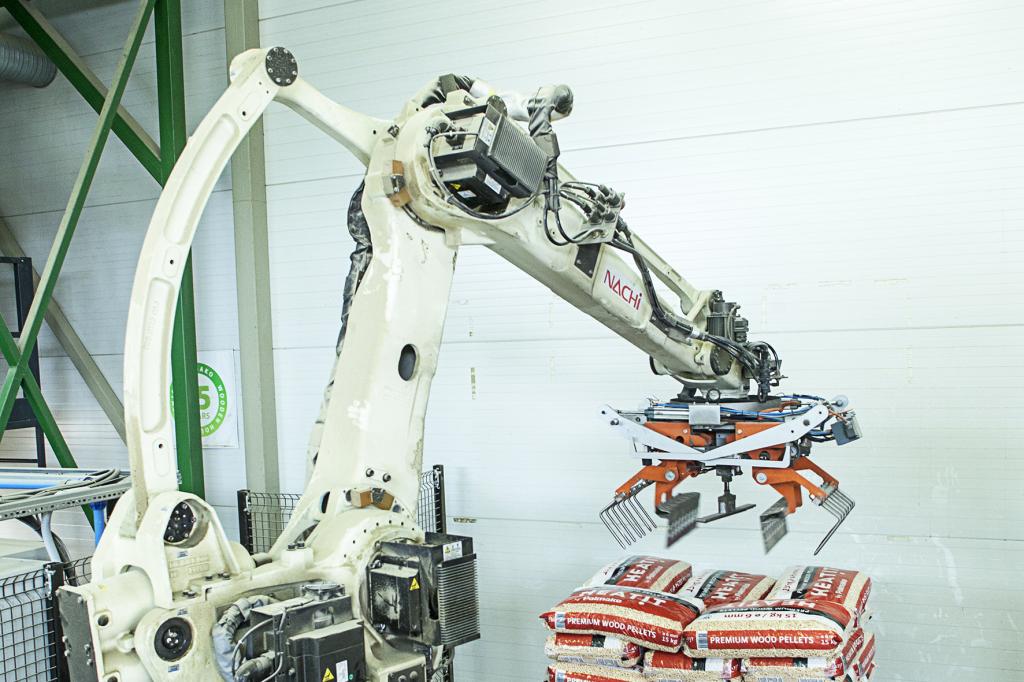

Bigger items like fence panels are wrapped in the heat shrink film after painting. Shrink wrapping helps our products no longer be vulnerable to external damage caused by dust, dirt or moisture. Shrink wrapped packages are hard to damage and are perfect for transporting. The package remains attractive and in the best condition when reaching the customer.

Pressure treatment (impregnation)

In order to extend the service life of timber, products are treated with impralit®-KDS (HC3, HC4) and Embalit (HC3) wood preservatives.

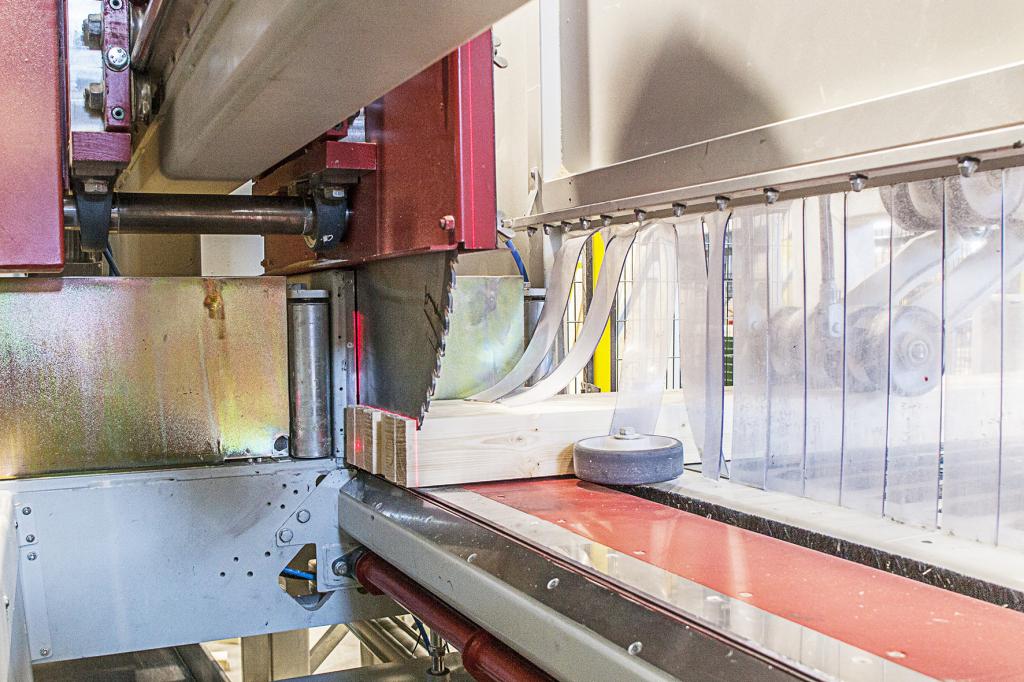

The preservative penetrates deep into the wood with the help of a vacuum and pressure. In this case, a vacuum is initially generated in the cell cavities thereby evacuating the air inside them. The cavities are then filled with preservative solution which is forced into the wood under high pressure. For vacuum pressure, different processes are used depending on the type of wood, environment and end purpose, but the majority of Palmako timber is treated according to European Standard EN351-1 to meet hazard classes HC2, HC3 and HC4.

Green or brown impregnated products have been treated with Impralit®-KDS wood preservative from Rütgers Organics GmbH. It is a water-borne, chromium-free wood preservative for the prevention of attack by insects, soft rot and fungal decay. It also offers temporary protection against blue stain and mould. Embalit P/Embacolor CG by Hoetmer b.v. is a grey coloured wood preservative system based on the active compound propiconazole. Wood treated with this is free of heavy metals and can be used in hazard class 3. It protects the wood from decay and preserves the wood for many years.

Scheme

Wood is put into the tank & pre-vacuum begins.

Air & moisture is pulled out from wood cells.

The tank is filled up with impregnation liquid.

With hydraulic pressure, liquid is pressed into wood.

The tank is emptied.

Final vacuum pulls out unnecessary impregnation liquid.